Anchorage points

At PS Stage, we have everything you need in anchor point systems to ensure the safety of your projects. Trust us to make your production shine without compromising your team's peace of mind!

At PS Stage we know that safety comes first in any event or theatrical production. As leaders in event, stage and theater equipment, our commitment is to ensure that your setup is not only spectacular, but also safe and reliable. In this category we focus on anchor points, those devices that guarantee the stability of your structures and systems at height. Let's break it all down so you can make the best decisions!

What is an anchor point?

Anchor points are a key piece of security systems in theaters and stages. They serve to connect elements safely to a structure, allowing loads and movements to be supported without compromising the stability of the system. From the suspension of lights and decorations to the anchoring of fall arrest systems for personnel, these devices are essential.

Security systems in theaters and stages

In modern settings, where productions require increasingly complex structures, approved anchoring systems are an essential requirement to meet the highest safety standards. At PS Stage we work with a wide range of anchoring devices designed to satisfy any stage need.

You may also be interested in our category of slings, shackles for slings, brakes for safety ropes or safety cables

Anchor point regulations

When talking about security, regulations are an issue that we cannot leave aside. Approved anchor points must comply with specific regulations that guarantee their quality and resistance.

In Europe, the most relevant regulation is EN 795:2012, which regulates anchoring devices used as part of fall arrest systems. This standard establishes:

- The minimum resistance that an anchor point must withstand (generally 10 kN or 1000 kg).

- The different types of anchoring devices (which we will talk about later).

- Installation and maintenance requirements.

Complying with these regulations is not optional; It is mandatory to guarantee the safety of all those involved in production.

Types of anchor points

There are different types of anchor points, each designed for specific applications. Here we explain the main ones:

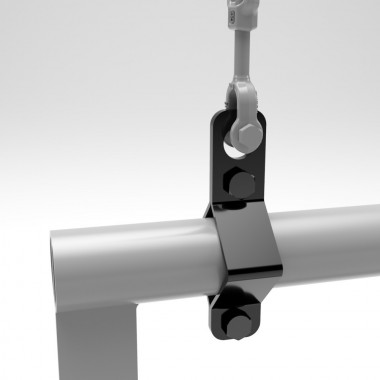

Fixed and structural anchor points

Fixed anchor points are those that are permanently installed in a structure. They are usually made of resistant materials, such as stainless steel, and are fixed using special screws or welding.

Advantages: High resistance and durability. They are ideal for systems that require constant anchoring.

Common applications: Fastening light poles, heavy sets or stage systems.

The importance of the direction of the fall in fixed anchor points

One of the key factors when installing a fixed anchor point is to consider the direction of the possible fall. The device must be designed to support loads in the intended direction, minimizing the risk of failure. Therefore, it is crucial to perform a technical analysis before installation.

Temporary Anchor Points

As their name indicates, temporary anchor points are designed for specific uses. They are usually portable and easy to install and remove.

Advantages: Flexibility and speed of installation.

Common applications: Short-term setups, such as concerts or temporary events.

Counterweight anchor points

Counterweight anchor points are mobile systems that use weights to ensure stability. They are ideal for situations where drilling or permanent fixings cannot be made.

Advantages: They do not damage structures and can be moved as needed.

Common applications: Flat roofs or scenarios where drilling is not allowed.

Installation of anchor points

The installation of approved anchor points is a process that must be carried out following strict safety guidelines. Below, we share the key steps:

- Preliminary analysis: A technical study to identify the ideal location and the loads that the anchor must support.

- Selecting the appropriate device: Choose between fixed, temporary or counterweight anchor points, according to needs.

- Professional installation: Installation must be carried out by a specialized team to ensure correct operation.

- Resistance tests: Before using the system, tests must be carried out to verify that it complies with regulations.

Periodic inspections of anchor points and maintenance

An anchor point is only as safe as its maintenance. At PS Stage we always recommend carrying out periodic checks to ensure optimal operation.

Frequency: At least once a year, or more frequently if devices are exposed to extreme conditions.

What to check: Corrosion, mechanical wear, deformation or any other sign of deterioration.

Maintenance: Replacement of damaged parts, cleaning and lubrication if necessary.

How is the strength of anchor points measured?

It is measured in kilonewtons (kN). The regulations require that approved anchor points withstand at least 10 kN (equivalent to 1000 kg).

What are the 4 types of anchoring?

- Fixed.

- Temporales.

- By counterweight.

- Movable (when flexibility in location is required).

How are anchor points classified?

According to the EN 795 standard, they are classified as:

- Type A: Structural fixed.

- Type B: Temporary portable.

- Type C: Lifeline systems.

- Type D: Horizontal rails.

- Type E: Contrapesos.

How many kg should an anchor point support?

At least 1000 kg or 10 kN, according to EN 795.