Industrial Hinges

Choosing the right industrial hinges is essential to ensuring the safety, functionality, and aesthetics of your event and concert venues. At PS Stage, as experts in stage and theater equipment, we'...re here to help you select the solutions that best suit your needs, ensuring the success of your productions.

Read more

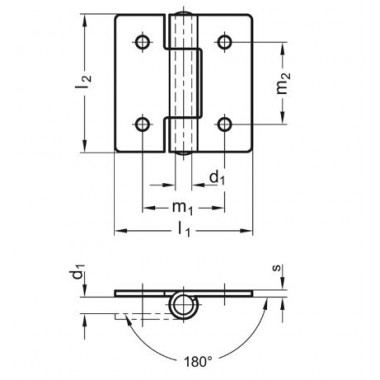

What are industrial hinges?

Industrial hinges are mechanical devices that allow the rotation of two elements, facilitating movements such as the opening and closing of doors, lids or panels in large equipment and structures. Unlike conventional hinges, heavy duty hinges are designed to support heavier loads and withstand harsh environmental conditions, ensuring optimal durability and performance in demanding applications.

Types of industrial hinges

There are various types of industrial hinges, each designed for specific applications. Below, we detail the most common ones:

Piano hinges

Also known as continuous hinges, they extend along the entire length of the surface they connect. They are ideal for long doors or panels that require uniform and stable support. They offer balanced weight distribution and are common in equipment boxes and machinery covers.

You may be interested in our category of industrial clamps, Anchor points or Black sling

Removable hinges

These hinges allow quick separation of joined components without the need for tools. They are useful in applications where frequent disassembly is required for maintenance or transportation. An example is hinges with removable pins, which make it easy to disconnect moving parts.

Friction or constant torque hinges

Designed to maintain a fixed position without the need for additional locking mechanisms. They are ideal for applications where a door or panel is required to remain in a specific position, such as adjustable screens or access covers.

Spring-loaded hinges

They incorporate an internal spring that facilitates the automatic opening or closing of doors or lids. They are common in security doors that must close automatically after being opened, thus guaranteeing safety and operational efficiency.

Adjustable Bisagras

They allow precise adjustments to the alignment of doors or panels after installation. They are essential in applications where precision is crucial, ensuring smooth and unobstructed operation.

Materials of industrial hinges

The choice of material is crucial to ensure the durability and performance of industrial hinges. The most common materials include:

Steel

Renowned for its exceptional strength and durability, steel is a popular choice for hinges that must support heavy loads. However, it is susceptible to corrosion if not treated properly, so it is recommended for use indoors or in controlled environments.

Stainless steel

It offers excellent corrosion resistance, making it ideal for outdoor applications or in humid environments. Although it is more expensive than conventional steel, its durability and low maintenance compensate for the investment.

Brass

Known for its aesthetic appeal and corrosion resistance, brass is common in decorative applications or where appearance is important. It is less strong than steel, so it is used in light to medium load applications.

Aluminum

Lightweight and corrosion resistant, aluminum is ideal for applications where weight is an important consideration. However, it is less resistant than steel, so it is used in moderate load applications.

Factors to consider when choosing industrial hinges

Selecting the appropriate industrial hinge is essential to guarantee the safety and efficiency of your structures. Here are some key factors to keep in mind:

Loading capacity

It is essential to ensure that the hinge can support the weight of the door or panel it will support. Insufficient load capacity can cause mechanical failure and compromise safety.

Frequency of use

For applications that involve frequent use, it is advisable to opt for highly durable hinges that can withstand repeated opening and closing cycles without significant wear.

Environmental conditions

Considering the environment in which the hinge will be used is crucial. In corrosive or humid environments, it is preferable to use corrosion-resistant materials, such as stainless steel or aluminum.

Aesthetics

In applications where appearance is important, such as theaters or stages, choosing a properly finished hinge can improve the overall aesthetics of the structure.

Maintenance

Some hinges require regular maintenance, such as lubrication or adjustments. It is important to consider accessibility and ease of maintenance when selecting the right hinge.

Applications of industrial hinges in events and concerts

In the world of events and concerts, industrial hinges play a crucial role in various applications:

Modular scenarios

The hinges allow the secure connection of stage modules, facilitating quick and efficient assembly and disassembly. Removable hinges are especially useful in these applications, allowing for flexible and adaptable configuration.

Access doors

In temporary structures, such as tents or cabins, industrial hinges ensure the smooth operation of doors and access panels, guaranteeing the safety and comfort of users.

Equipment boxes

Piano hinges are common on equipment cases, providing smooth and secure opening and closing, protecting sensitive equipment during transport and use.

Scenographic elements

In the creation of mobile scenic elements, hinges allow controlled and safe movements, adding dynamism and functionality to productions.

If you are interested in equipment for events and concerts you may also be interested in visiting our string brakes section, tube caps or our shackles