Rope brakes

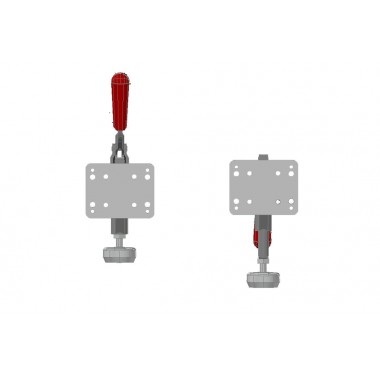

What is a rope brake?

A rope brake, also known as a safety cable brake, is a device designed to prevent a rope from moving from its locking point. These systems are essential to ensure that suspended elements on a stage or theater remain in their desired position, avoiding unwanted movements that could compromise the safety and integrity of the production.

How does a rope brake work?

The operation of a rope brake is based on a mechanism that holds the rope using cams or jaws. When activated, the brake immobilizes the rope, preventing its movement. By releasing the brake, the rope can move freely. This mechanism is essential for controlling and securing loads on stage systems and other stage equipment.

You may also be interested in visiting our Wire ropes, our steel chains or our load lifting systems.

Types of rope brakes

In the entertainment world, there are several types of rope brakes, each designed for specific applications. Below, we present the most common ones:

1. Sheet brakes

Sheet brakes allow free movement of the rope when tensioning it, but block movement in the opposite direction. To release it, simply stretch the rope out of the jaw. They are common in nautical and stage applications where quick and secure adjustment of ropes is required.

2. Tramline systems

In theaters, staging systems use rope brakes to control and secure suspended elements. These brakes are mounted on a locking rail and have a lever that, when raised, presses a moving cam against a stationary cam, immobilizing the rope. They are essential to maintain the position of the poles and other scenic elements.

3. Retention stops

Retention stops act by altering the diameter of the rope to prevent it from moving beyond a certain point. For example, on a well rope, a knot can be tied at the end to prevent the rope from passing completely over the pulley and falling into the well. This method is simple but effective for applications where a physical stop of the rope is required.

What are spring brakes?

Spring brakes are devices that use the tension of a spring to absorb the energy of a moving rope, reducing its speed in a controlled manner. They are common in applications such as zip lines, where users need to be safely decelerated at the end of the course. These brakes provide smooth and controlled deceleration, improving system safety.

How to choose the right rope brake?

Choosing the right rope brake depends on several factors:

- Application Type: Determines whether the brake will be used in a traverse system, for sheet control, or in other specific applications.

- Rope diameter: It is crucial to select a brake compatible with the diameter of the rope to be used. Some brakes are adjustable to accommodate different diameters.

- Expected load: Consider the maximum load that the brake must support. It is essential that the brake can handle the load without risk of failure.

- Material and construction: Opt for brakes made from high-quality, durable materials, especially if they will be used in demanding environments.

- Release mechanism: Some brakes offer quick release mechanisms or additional security systems, such as the possibility of incorporating a padlock to prevent unauthorized use.

Installation and maintenance of rope brakes

The correct installation and maintenance of rope brakes are essential to ensure their safe and efficient operation.

Installation

- Preliminary inspection: Before installation, verify that the brake is in perfect condition and that it is compatible with the rope and the desired application.

- Proper assembly: Follow the manufacturer's instructions to mount the brake correctly, making sure it is securely attached and aligned with the rope.

- Initial Testing: Once installed, perform tests to ensure the brake is working properly, locking and releasing the rope as necessary.

Maintenance

- Regular inspections: Periodically check the brake for signs of wear, corrosion or damage. Pay special attention to cams, springs and other moving components.

- Cleaning: Keep the brake clean and free of dirt, dust or debris that could affect its operation. Use appropriate cleaning products according to the manufacturer's recommendations.

- Lubrication: If indicated by the manufacturer, lubricate the moving parts of the brake to ensure smooth operation and prolong its useful life.

- Component Replacement: If any component shows signs of excessive wear or damage, replace it immediately to maintain system safety and efficiency.

If you are interested in equipment for events and concerts you may also be interested in visiting our industrial hinges section, industrial adhesive tapes or our tie straps